Mass customization: the future of manufacturing

Like to skip ahead in articles? Jump to the sections that interest you most:

- Industrial Revolution 1.0: Machines

- Industrial Revolution 2.0: Modern factories

- Industrial Revolution 3.0: The digital revolution

- Manufacturing 3.0 Mindset: what’s different?

- Mass customization case study: the Wedge

Words like “manufacturing” or “production line” naturally bring to mind images of large buildings, filled with machines and hundreds of employees toiling endlessly, each creating some component of a product. However, this association is not how many new products are actually produced — nor is it the height of efficiency we’ve been led to believe.

Modern manufacturing, manufacturing 3.0, is a fairly recent development, having awaited the growth of a mass consumer market as well as the development of mass-production techniques. Earlier production was done largely by hand prior to the Industrial Revolution, with skilled artisans providing labor using hand tools and great amounts of time (manufacturing 1.0).

The manufacturing we all think of — assembly lines and factories — has only been around for about 100 years. This system, manufacturing 2.0, worked well for mass production, but it has vast limitations as well.

We’re sitting on the cusp of a third Industrial Revolution – a digital one, driven by new technologies and new materials. So if we don’t want to repeat history, we better understand it.

Industrial Revolution 1.0: Mechanization

Let’s travel back to England, circa the late 18th century. Working with your hands was the norm. From cobbled leather shoes to finely joined wood cabinetry, this pre-mechanized culture was chock full of original products handcrafted by artisans who grew up learning their respective trades. (We’d probably call these goods “designer” today.)

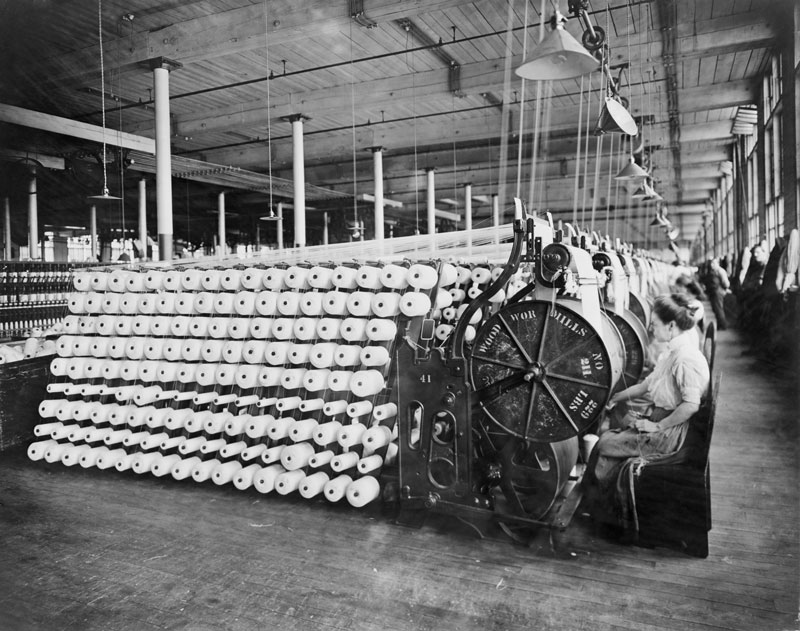

The first Industrial Revolution originated in Britain’s textile industry. What was previously done by hand in homes and weavers guilds consolidated with inventions like the Spinning Jenny. Removing these tasks from individual hands and bringing them together in a single cotton mill created the world’s first factory.

Industrial Revolution 2.0: The Assembly Line

For about 150 years this was pretty revolutionary. (Less cool were the horrible working conditions, child labor issues and environmental degradation … but hey, nothing’s perfect.) And while this system was better than we had ever done, it was hardly anything until Henry Ford came along.

Ford’s moving assembly line, together with the steam engine, electricity and a few other inventions, gave us the age of mass production. Changing the face of how we created goods, customization was sidelined as mass production ushered in the age of modern economies and vast production empires.

Thus Industrial Revolution 2.0 was born. More productive, it made goods cheaper and more available to the masses … and hey, it gave us phrases like “you can have any color you like as long as it’s black.”

Mass production changed a bit with W.E. Deming and the LEAN process in the 70s and major outsourcing to reduce labor costs in the 80s, but for essentially the last 80 to 100 years, we have been manufacturing like Henry Ford did.

Industrial Revolution 3.0: Mass Customization

This mass production mindset gave us consistent, cheap goods, we all saw it’s limitations. Products designed for the masses and built for a disposable lifestyle aren’t as great in practice as they sound in concept. And while custom work suits both individual needs and tastes, it typically results in expensive products that are few in quantity, slow to produce and hard to standardize.

The 1990s saw the rise of a new idea, existing in the midst of a customization versus mass production dichotomy. This new vision for manufacturing (3.0) — mass customization – merges the personalization of customized goods with the efficiency of mass production.

Dell is probably the most famous early success story. When Michael Dell decided he would create a distinct PC for anyone willing to buy it, he probably had no idea how big that idea would grow.

Dell offered consumers not only what they wanted but also something they hadn’t seen before: the ability to choose the design, software and hardware options best suited for their individual needs. That groundbreaking concept exploded onto the market and launched Dell to the top of PC manufacturers.

There weren’t many brands that could replicate Dell’s success, however, showing that the market wasn’t quite ready for 3.0. (Think Levi’s customized jeans or personalized M&Ms.) In an where the most popular coffee shop serves 87,000 different kinds of drinks, real mass customization is just around the corner.

The biggest factor holding ‘90s retail brands back was a lack of technology. While the manufacturing 2.0 factory relied on cranking out thousands of indistinguishable widgets to control cost, thanks to today’s technology, producing much smaller batches tailored precisely to a specific design intent, user need or other factor is more economical than ever. We can now utilize these advances and our knowledge from the first two revolutions to decentralize our process and create in brand-new ways.

Manufacturing 3.0 mindset

Luckily, we started Shield in the midst of the third Industrial Revolution: manufacturing, meet the digital revolution.

3D printing is a large part of the Industrial Revolution 3.0 but there are also smarter robots, big data, better material choices and much more powerful software systems. All of this allows us to digitally prototype a product or a process in much more robust systems, creating more testing and validation before we build.

Perhaps most importantly, there is a mental shift away from cookie-cutter solutions made with poorly designed details and cheap materials.

Buying architectural furniture or products is has tended to be a fairly conventional process. There are sizes, material options and a few variables pre-selected for consumers, all available in a glossy catalog with lots of fine print. Prices are hidden or shown at a high margin to be laughable. Why, with so many forward-thinkers operating around the design profession, does the product industry insist on pushing widgets via an archaic pricing model?

We think the transparency of the Internet Age and the advances of making technology has changed all that. Shield is reviving the idea of mass customized products through the web, advanced software and cutting-edge manufacturing techniques and systems. Personalized products and furniture may have long been a fantasy of many designers … until now.

We know that we’re not the only smart people out there seeking solutions, but we’ll offer up one example. For instance, our custom spec system allows designers to control our product, removing all the barriers and restrictions that typically constrain the design process. This near-custom experience is a step beyond traditional product lines that can be personalized per project. And it’s miles better than what you find off-the-shelf.

Typical product lines may soon be a thing of the past. Today’s technology, machinery and consumer expectations allow designers to do what they do best … design.

Mass customization case study: the Wedge

This thinking led us back to our own customers when we developed the Wedge line of casework. We had the best box money could buy and we could make it any size you could imagine, but we only had solid surface finishes available. While that model was great for our product’s durability but what kind of flexibility did that show? Was this the best we could do? Was it really manufacturing 3.0?

We weren’t asking our users to think entirely differently about what a product line is, just what sizes it could be. That had to change and the Wedge was born.

Many products are designed for a specific use case, which is largely for manufacturing efficiency. The Wedge was developed with a new type of manufacturing model in mind. It puts the needs of its users ahead of factory-like efficiency while holding the product’s price point within market norms.

Many products are designed for a specific use case, which is largely for manufacturing efficiency. The Wedge was developed with a new type of manufacturing model in mind. It puts the needs of its users ahead of factory-like efficiency while holding the product’s price point within market norms.

This modular cabinet line is easily tailored to a variety of space through hardwood selection and corresponding solid surface colors. It offers the signature durability of our original casework lines, the limitless customization of our flexible manufacturing process and now, the design options to meet the values we champion.

No two projects are alike, which is the beauty of the Wedge. It has recently been installed in everything from a design firm’s corporate lobby to the renovated locker room of an NBA team.

The Wedge offers beauty, durability and flexibility, combining both design and function fully. It is the future of the product design – a product line that is both standard and fully customizable at the same time.

We started with a product that we thought was all we needed: the Curve, Shield’s original casework line that’s perfect for critical environments. However, we quickly realized our partners were looking for more — sometimes they needed a melamine interior to cut cost, or the design flexibility of a wood door, so we created the Cube and the Wedge.

Once we created the Wedge and its myriad possibilities, we realized what we were really great at offering wasn’t a one-and-done product, but instead a system. We realized it didn’t matter how wide or tall you want our products to be. Everything we produce is designed from the get-go to be fully customizable, scalable and modular.

This thinking has led us to create a product line around our once-custom (but no longer) nightstand, the Monolith, as well as our locker line, the Vault. Our engineering elves are working on more products to roll out throughout 2015 as well. Creating the Wedge allowed us to open ourselves to the possibility of mass customization and bring all of its benefits to our partners and their clients.

Sorry, the comment form is closed at this time.