How modularity promotes sustainability

Modularity first made its way into the world in the 1930s, with Albert Farewell Bemis’ architectural theories. It has since been adopted and applied to a variety of industries, including computer programming, biology, mathematics and industrial design. There are many benefits of modular products, including their quicker production speed and lower costs. Today we’re breaking down the benefits of modular products and their architectural applications in a number of industries, as well as how we apply modularity to our very own products.

What is modularity?

Modularity can vary in definition, depending on the context and industry. However, in general, modularity refers to something constructed of standardized units—modules—that can be separated or combined to create a complete product.

A simple example is a sectional couch. Composed of multiple small, individual units, a sectional couch can be rearranged in a variety of ways, depending on the space and user’s preferences.

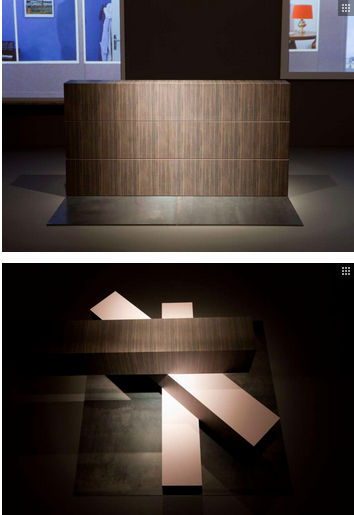

In our terms, modularity looks like putting separate pre-fabricated panels together which creates a full product, take our headwalls for example. Beginning as multiple parts, once everything is put into place, you see the entire vision and installation time is cut in half.

Promoting sustainability

Modular products have a number of benefits for both man

First it was the kit home in the early to mid 1900s. Later, it was furniture—couches, cabinets, chairs, desk systems. Now modularity is employed in hundreds of ways by various industries. Widely prevalent in the architecture and manufacturing world, modularity saves both businesses and consumers money and better meets their needs. There are a number of benefits of modular products for manufacturers and clients alike, but perhaps some of the most important benefits are those for the environment. Here’s a look at how modularity promotes sustainability.

Faster production time

Broken down into small, individual pieces, modular products take less time to produce. Manufacturers have shorter learning curves in understanding the production of each small item, and the overall speed of production increases. This not only benefits clients and manufacturers but also the environment. Faster production means less energy used to power tools and facilities while products are manufactured, conserving the Earth’s natural resources.

Easily customized to client needs

Modular products are flexible in nature. Furniture systems, in particular, are easily rearranged in a number of ways to meet changing customer needs and preferences. With such customizability, customers don’t need to buy an entirely new product when circumstances change. Small space size for the couch? Just tweak the layout a bit. New needs for your casework system? Rearrange it. The same product can be modified again and again in a changing environment, saving landfill space and product materials.

Quick fix of broken parts

On regular products, when one piece breaks, the whole product is often done for. Even if there’s hope of fixing the product, it takes a lot of time and money to replace one piece. In modular products, however, it’s an easy fix. As the product was built and constructed https://www.buyamoxil-amoxicillin.com piece by piece, repairs of this nature are simple and affordable; the module can be replaced without any other changes. Moreover, the customer can continue using the product for years rather than simply tossing it in the landfill and buying a new one.

Easy to update

Similar to customers’ ability to reorganize a product to fit changing needs, manufacturers can easily update modular products to meet the evolving needs of the mass public. Updated modular products can often use many of the modules from the old product with changes in just a few modules or aspects of the product. This allows for quicker production and recycling of old parts, both of which benefit the environment.

Multi-functional products

Just as modular products are easily rearranged to fit changing environments, they’re also easily repurposed. A chair opens up into a couch. A seating system compacts down to a table. A cubicle-style work desk becomes an open office-style system. The customizability of modular products allows customers to utilize the product in a number of ways for a variety of functions.

Modularity promotes sustainability

The recyclability, flexibility, learnability and functionality of modular products make them highly conducive to sustainability. By creating products that can be modified to fit new environments and meet changing needs, manufacturers help reduce the throwaway culture. Moreover, these products are more quickly built, reducing the amount of resource use and, as an added benefit, lowering the final cost for the client.

Therefore, modularity benefits not only clients and manufacturers, but also the environment by reducing landfill waste and conserving electricity. For more information on the benefits of modular products, check out our blog post.

The benefits of prefab | Shield Casework | Jan 25, 2016 at 4:11 pm

[…] combined with modularization, increases productive and ROI. See our blog post on modularization for more information on both the direct and indirect benefits of these two […]