The benefits of manufacturing in America

In mid-April, Steven Kilzer published a blog post on Maker’s Row about the benefits of manufacturing in America. Capital, the business Steven founded, designs and makes high-quality eyewear. Capital owns the factory where all it products are made, allowing Steven and his team to maintain control over every single detail of the product. He acknowledged that it’s hard work—a lot harder than simply outsourcing to another already-established factory nearby and exceptionally more difficult than outsourcing to a cheap factory in another country—but the benefits of such work are far more important.

Doesn’t sound like much fun, but we agree wholeheartedly with Steven. A little over a year ago, we moved to our own facility in North Kansas City, and we set up shop right next door to our office. Like Steven, we have total control over the design process. It’s definitely more difficult than it could be, but we know that easier doesn’t always mean better.

If you have time to read all of Steven’s post, you should, as it provides great commentary concerning manufacturing in America. However, here’s a brief overview of the main benefits to in-house manufacturing that Steven detailed and how these benefits apply to our work at Shield.

1) Knowing the processes improves the design

Steven said that to be the best designer possible, one must have a deep knowledge of the processes used to make the product. For Capital, this meant experimenting with ways to apply durable, customizable text to sunglasses.

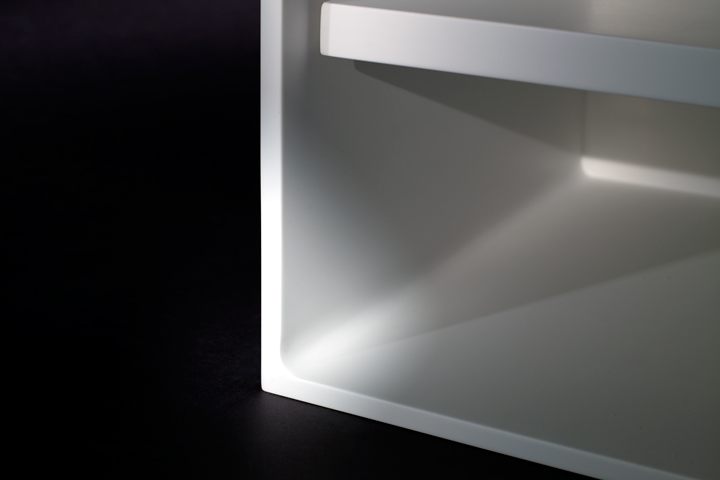

For Shield, this has meant experimenting with every product and finding the best materials, hardware and manufacturing processes to build it. In architecture and manufacturing, there is often a disconnect between what the designer wants done and what can realistically be done. A designer may be able to draw an amazing piece of architecture that looks great on paper but that can’t truly be carried out in the specified time frame and budget. By building our products next door to where we design them, we can not only solve these problems more effectively, but we can also better design them next time.

2) Face-to-face communication speeds up production

As Steven said in his post, developing products is an ongoing process. When he has a product idea, he walks the few feet to the studio and discusses the idea with project managers, eliminating difficulties created by time zones and language barriers.

At Shield, this is incredibly important. Most projects are not simply designed and then carried out with 100 percent ease. What may seem a simple project at first is not actually so simply. The production process is different for each project, and our designers and engineers communicate difficulties throughout the day.

When our project manager finds a problem, he simply walks into the office and talks it out with our engineer. There’s no added barriers, no waiting for an email response. The problem is solved, right there, face-to-face. This greatly speeds up the entire process and ensures a meticulously designed and crafted product. (Read more about our quick production process and how long it takes us to make a product here.)

3) Our motives are clear

Perhaps one of the most important benefits to producing in the U.S. is that you have control over the product and can ensure that each and every aspect of it was built with high attention to detail. As Steven said, outsourcing production of a product to the cheapest place possible shows that the company cares more about low cost than high quality. It’s not that products made in other countries are of low quality, but the quality certainly wasn’t first on the list of considerations.

Producing in the USA, however, sends a different message, and that’s the message we send at Shield. Could we have chosen to simply design our products in our office and then have a cheap company overseas produce them? Sure, but our knowledge of the product and it’s true quality would have drastically decreased. We wouldn’t have concrete knowledge of the working conditions the manufacturers underwent. We wouldn’t see the product being made. We really would not have any idea how the product got from point A to point B, and that’s our biggest concern. We do care about price, but what we care about most is quality.

By manufacturing in America, we ensure that we never sacrifice quality for price.

Sorry, the comment form is closed at this time.