Shield’s custom work process

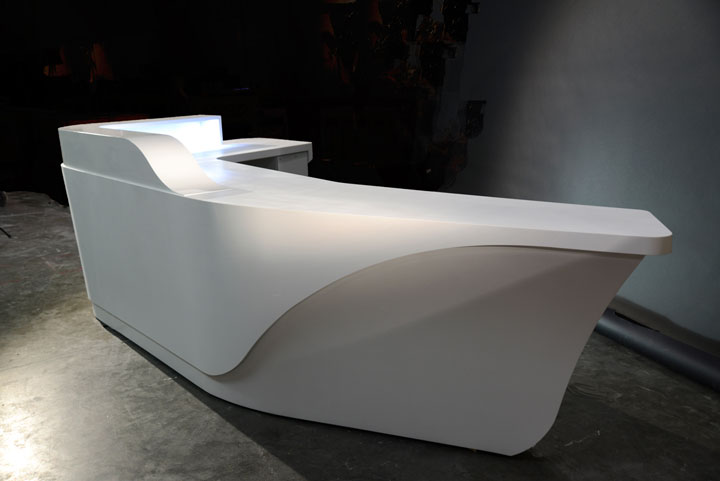

You’re probably aware that, at Shield, we do a lot of custom work, whether that means customizing one of our already-engineered products or figuring out how to build a completely new one. Thus, we have a specific process for desks and custom work. It’s pretty straightforward, but we wanted to share it with you. Here is Shield’s custom work process.

Step 1: Discovery

Whether you’ve got a fully formed idea of the product you want or not the slightest cue of what you need, we’ll work with you to develop a plan. We’ll explore options and refine your ideas into a cohesive product plan. We engage in a collaborative, creative process to make sure all of your needs are met—and we do mean all of them—so we can begin making the physical product.

Step 2: Engineering

So we’ve worked together to create and refine the product. You’re happy, we’re happy, now it’s time to start making the idea a reality. Our skilled engineering team determines exactly how to fabricate the product. They figure out how the product will be built while ensuring it will look like you imagined it would look, function like you need it to function and cost as much as you expected it to cost.

Step 3: Fabrication

Once the plans for fabrication are ready to go, we start really bringing the product to life. Our team of skilled craftsmen build the product in our 10,000 square-foot shop located next door to our office, putting it together step-by-step, piece-by-piece. If any problems arise, they’re quickly reconciled with our engineering team, meaning your product is handcrafted to perfection.

Step 4: Delivery and Installation

The product is built (and everything looks great). Now it’s time to send it your way. Depending upon the product and job requirements, we either ship the product to you for your handling or we install the piece in-person at your facility. Whatever the product, we work with you to make sure your needs are fully met.

[vc_separator type=”transparent” up=”20″ down=”20″]

Sorry, the comment form is closed at this time.